Inkwell

ABSTRACT

Microscopy plays a crucial role in hematology and diagnosis of infectious diseases worldwide. For malaria alone, more than 200 million slides are read by manual microscopists every year. High quality thin blood smears are essential for subsequent microscopy examinations including malaria microscopy, but are hard to make in field settings. Existing devices for assisting in making thin smears are available but are limited by cost or complexity for wider use. Here we present Inkwell, a portable mechanical device capable of making high quality thin blood smears in field settings. Inkwell is simple, low-cost, does not use electricity, and requires minimal training prior to use. By utilizing passive dissipative dynamics of a spiral spring coupled to an air dashpot with a tunable valve - we demonstrate a highly tunable mechanism for constant velocity smears at prescribed angle. Inkwell is capable of producing high quality blood smears of tunable cell density with more than 12 million individually distinguishable red blood cells on a single slide. The current design, which exploits precision manufacturing of a 17 cents plastic syringe and a spring, can be printed on a standard 3D printer with overall unit cost of less than a few dollars in large quantities. We further present usability tests to confirm performance over 10,000 unit cycle operations with no degradation in quality of the smear and demonstrate ease of use with minimal training. Inkwell enhances the broader toolbox of open innovations in diagnostics for providing high quality medical care in low and medium resource settings. Combined with rise of 3D printing, Inkwell presents an alternative to traditional centralized manufacturing and opens up distributed manufacturing of medical diagnostics in global context.

BIG QUESTION

“How can we aid technicians with varying skill levels in producing consistent high-quality thin smears in the field using only simple, low-cost parts?”

Slides imaged per year:

100-200 million

slides

Comparable product cost:

$1000

per unit

Inkwell cost:

$15

per unit

Inkwell smears have up to:

13-16 million

red blood cells

What is Inkwell?

Malaria continues to devastate communities worldwide, with over 200 million cases each year and the greatest burden falling on low- and middle-income countries (LMICs). Microscopy remains the gold standard for diagnosis, yet its effectiveness hinges on high-quality thin blood smears. Globally, 100–200 million slides are examined annually for malaria, but the vast majority are still prepared by hand. This manual process introduces variability—overlapping cells, uneven density, and shearing—that obscures parasites and leads to misdiagnoses. The consequences are severe: delayed treatment, continued transmission, and preventable loss of life.

Automated smear-preparation equipment exists but is prohibitively expensive and dependent on electricity, making it inaccessible to the very clinics where malaria burden is greatest. This inequity leaves frontline health workers without the tools they need to provide accurate, timely diagnoses.

Inkwell fills this gap. Specifically designed for resource-limited field sites, Inkwell is a low-cost, electricity-free device that reliably produces high-quality smears regardless of user experience. Built from off-the-shelf components and reproducible with 3D-printing, it offers scalability and local maintainability at a fraction of the cost of conventional systems.

Door-to-door healthcare workers manually making blood smears in the field.

Assembling an Inkwell device

Latest Inkwell iteration

How does it work?

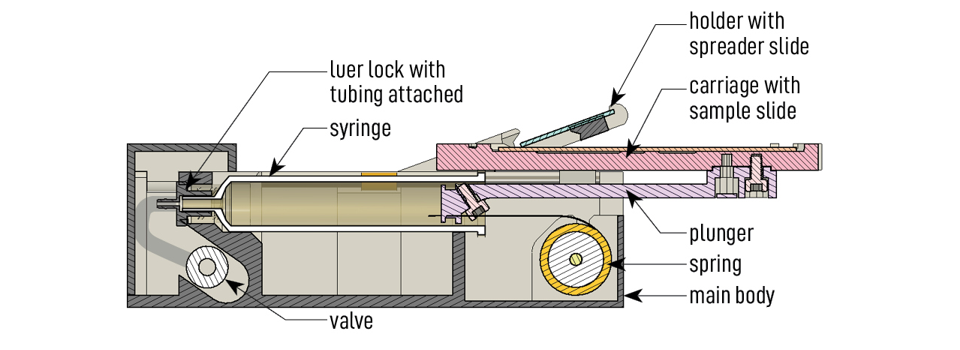

The mechanism of Inkwell lies in the spring, piston, and valve combination, allowing for controlled velocity for making the thin smear. The traveling carriage is actuated by a constant-force spring and damped by a vacuum pressure in the form of tunable airflow. While traditionally, this is done by using a dashpot, an ultra-low friction graphite piston costing ~$80 per unit, Inkwell uses a lubricated plastic syringe (~$0.20/unit) fitted with an adjustable needle valve ($0.50/unit), which can provide comparable smooth dampening. The tunable valve allows the user to further calibrate the desired density and thickness of the smears produced. Metal rods and sleeve bearings, along with adequate syringe lubrication, allow for extra smooth travel.

The spreader holder can be easily adjusted to various angles, while gravity and a level mechanism are sufficient to keep contact between the spreader slide and the sample slide. This constant contact is critical to produce an even smear, pulling the meniscus of RBCs along the length of the slide.

Data

Good thin smears are defined as having a large area in which RBCs are monolayered and densely packed, with very little overlapping. Evaluating thin smears made by hand versus using Inkwell, we found Inkwell smears exhibit an average cell density of 13k-16k cells/mm2 and a 97-97% slide coverage of monolayered RBCs, resulting in 13-16 million distinguishable RBCs, as compared to smears made by hand with 2.8k-4.4k cells/mm2, a mere 20-40% slide coverage, and a total of 2.8-4.4 million RBCs, respectively.*

To test the durability of Inkwell, we built a stress-test machine which simulates a technician operating Inkwell over thousands of cycles. The smears produced using a newly-built Inkwell compared to one that had undergone 10,000 cycles are comparable and are good quality smears.

*Smears done on Inkwell were produced using both human whole blood with anticoagulant agents and fresh finger-prick blood.

Scan of thin smear produced on Inkwell, 2D and 3D heatmaps showing cell density

Project Collaborators

To date, we have deployed hundreds of Inkwell units to collaborators across the globe, including in Uganda, India, Senegal, Liberia, Kenya, Tanzania, and Madagascar. Alongside distribution, we have conducted hands-on trainings with local health workers—many of whom had never before been trained to prepare thin blood smears. Remarkably, within a single training session, participants were able to consistently produce high-quality smears using Inkwell. This not only demonstrates the device’s ease of use but also underscores its potential to rapidly build diagnostic capacity in regions where skilled microscopists are scarce, ensuring broader and more equitable access to accurate malaria diagnosis.

This project is currently funded by Gordon and Betty Moore Foundation, Bill & Melinda Gates Foundation, Google, and Chan-Zuckerberg Biohub.